233x Filetype PDF File size 0.04 MB Source: ceh.cosmo-oil.co.jp

Environmental Performance

Oil Refineries

Oil refineries refine crude oil to produce Promotion of Efficient Energy

petroleum products such as gasoline, kerosene Use to Prevent Global Warming

and diesel fuel.

Large amounts of heat energy are required The introduction of cogeneration facilities is one

during the refining process, so the refineries measure being taken to use energy efficiently

are equipped with heaters, boilers and other at oil refineries. Cogeneration equipment makes

facilities. These facilities burn petroleum gas, a possible the supply of both heat and electrical

byproduct of fuel oil refining, releasing CO

2, power at the same time. By using waste heat

SOx, NOx and other gases. Cosmo Oil is occurring from electrical generation to generate

working to use energy efficiently to reduce CO2 steam, oil refineries can efficiently use this

emissions, while also working in many ways to energy—the process is more efficient than

reduce SOx and NOx emissions. using electrical generation equipment alone.

We are also working to reduce the amount of Operations at Cosmo Oil

water used in the refining process, and to make provided 39,500kW at the

the appropriate treatment of wastewater to Chiba Oil Refinery,

prevent water pollution outside the refineries. 17,500kW at the Yokkaichi

Petroleum Refining Process Oil Refinery, and 17,000kW

1. Crude oil is heated to the boiling point of at the Sakai Oil Refinery.

the various desired materials and By improving existing

divided into fractions infrastructure and by

Distillation (atmospheric distillation, precisely controlling

vacuum distillation, etc.) operations, a major

reduction in CO

2. Fractions are purified by eliminating 2 emissions

sulfur, nitrogen and metals is possible. For example,

Desulfurization (hydrodesulfurization through the introduction of Cogeneration facility

inverters, the recovery of at the Chiba Oil Refinery

unit) heat from heater exhaust gas, and the careful

3. The purified fractions are processed to checking and balancing of heat input and

provide added value waste heat energy, conservation can be

Conversion (catalytic reforming) promoted.

Cracking (catalytic cracking) At the Sakaide Oil Refinery, existing energy

4. The fractions (base materials) are mixed conservation programs were strengthened,

according to market needs resulting in major results in a very short time. As

Blending (gasoline mixing unit, fuel a result, the refinery was awarded the 2000

oil blending unit, lubricating oil Agency of Natural Resources and Energy

mixing unit) General-Director’s Award.

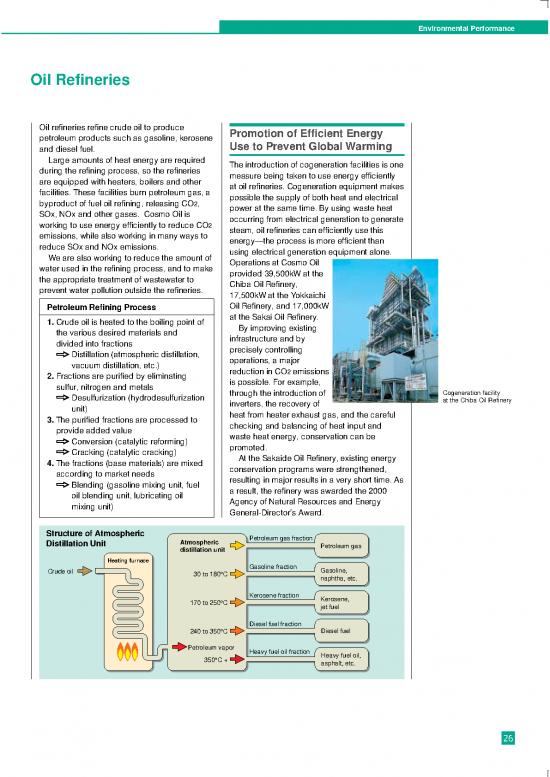

Structure of Atmospheric Petroleum gas fraction

Distillation Unit Atmospheric Petroleum gas

distillation unit

Heating furnace Gasoline fraction

Crude oil 30 to 180°C Gasoline,

naphtha, etc.

Kerosene fraction Kerosene,

170 to 250°C jet fuel

Diesel fuel fraction

240 to 350°C Diesel fuel

Petroleum vapor Heavy fuel oil fraction

350°C + Heavy fuel oil,

asphalt, etc.

̎̒

Environmental Performance

Preventing Air Pollution with For the Effective Use of Water

Flue Gas Desulfurization and Resources and the Prevention of

Vapor Recovery Water Pollution

We work to reduce emissions of SOx and NOx Seawater and industrial-use water are used in

gases by using fuels which are low in sulfur and oil refinery processes. Cosmo Oil strives to use

nitrogen in our oil as little water as possible by applying the

refineries’ heaters and recirculation of industrial water for cooling.

boilers. In addition, After being used for washing and other

low-NOx burners are refining processes, the resulting process

3

used to reduce the wastewater is processed in the oil-water

thermal NOx formed separation unit to remove oil, then undergoes

when atmospheric active sludge treatment and other processes to

nitrogen and oxygen assist in water pollution prevention.

react during

combustion, and flue Fuel Gas Denitration unit

which removes NOx from Promotion of Waste Reduction

gas desulfurization exhaust gases Through Volume Reduction and

1

and denitration units have been introduced to Recycling

remove SOx and NOx from flue gases. Electric

precipitators are also used to eliminate fine The major industrial waste products generated

particulates from exhaust gases. Through these by oil refineries are the sludge which occurs

actions, Cosmo Oil's four oil refineries have all during wastewater processing, and the spent

cleared regulations in the emission of SOx and catalysts from the refining process.

NOx, and are helping in the prevention of air Sludge is first dehydrated, then incinerated

pollution.* to reduce the quantity in incinerators which

For gasoline tanker trucks, the release of have been carefully checked for accordance

2 with dioxin emission regulations.

hydrocarbon vapors into the atmosphere

1 during loading is prevented through the fitting Spent catalysts are reused through

Flue gas denitration unit of vapor recovery units. reactivation treatments, the metals in spent

A unit which removes NOx from

exhaust gases. Ammonia and a * Please refer to data by site on page 41. catalysts are recovered, or recycled as a raw

catalyst are used to reduce the material in cement. Through this the amount of

gas, or adsorption using an

adsorption solution can be used. waste and the cost of new catalyst purchases

2 Hydrocarbon vapor are both reduced.

The gasified form of light

hydrocarbons

3 Process wastewater

Wastewater containing oil

discharged from refining 4

facilities. At the oil refinery, water Cosmo Oil Yokkaichi Kasumi Electric Power Plant Biotope

contained in the process To find a suitable application for the surplus heavy oil from the Yokkaichi Oil Refinery,

wastewater is eliminated with an

oil-water separation unit, treated the Yokkaichi Kasumi Power Plant is being constructed, with the aim of selling the

by secondary processes such as electricity generated at the facility. During the environmental impact evaluation

active sludge treatment, and

discharged. conducted prior to construction, however, it was discovered that two rare plant

4 Biotope species–kawatsurumo or Wigeongrass (Ruppia

“Biotope” is a German term maritima Linnaeus) and tsutsuitomo or Small Pondweed

combining bio, the Greek word (Potamogeton pusillus)–were on the construction site.

for “life” and tope, from the Greek

topos or place. It is a place Both are aquatic plants which grow in marshes and

where plants, insects, fish and ponds. The Yokkaichi Kasumi Power Plant is a biotope

birds can exist in symbiosis.

They are created by where the safeguarding of endangered species is

organizations, schools and promoted.

companies in their local area for

the purpose of environmental

protection. Protection of rare plants in the biotope

̎̓

no reviews yet

Please Login to review.