211x Filetype PDF File size 0.47 MB Source: www.humanitarianresponse.info

Technical Notes

Composting methods for organic waste

Introduction

The segregation of organic waste and production of compost is one of the most important activities when

managing waste. Organic material accounts for at least 60% of the total amount of waste generated in camps,

and Cox’s Bazar District in general. Organic material is easily decomposable. If not collected daily, it becomes

smelly and attracts disease vectors (rodents, insects). Ideally, organic material is segregated at source, at the

point of waste generation. When mixed with inorganic material, it reduces the market value of recyclables,

such as cardboard or PET bottles. Organic waste, if well segregated at source, can be turned into compost,

which is both a soil fertilizer and a soil amendment. Compost can be applied in tree plantation, greening

shelters, growing vegetables, restoration of soil, etc.

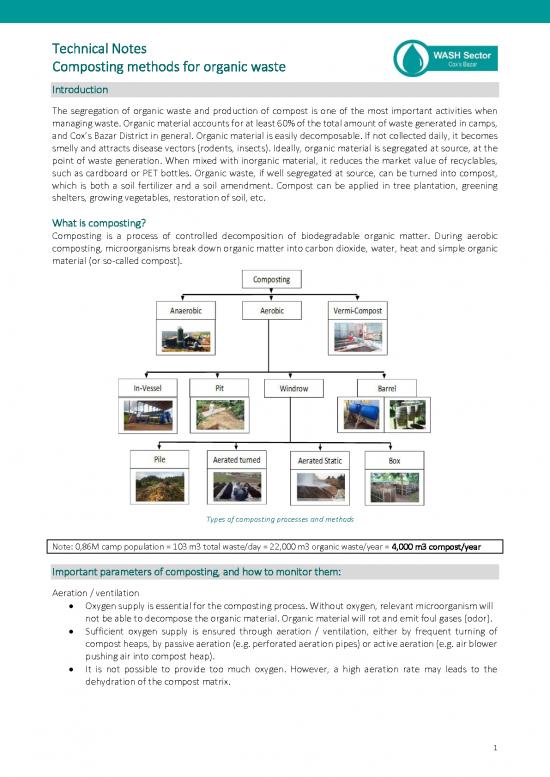

What is composting?

Composting is a process of controlled decomposition of biodegradable organic matter. During aerobic

composting, microorganisms break down organic matter into carbon dioxide, water, heat and simple organic

material (or so-called compost).

Types of composting processes and methods

Note: 0,86M camp population = 103 m3 total waste/day = 22,000 m3 organic waste/year = 4,000 m3 compost/year

Important parameters of composting, and how to monitor them:

Aeration / ventilation

• Oxygen supply is essential for the composting process. Without oxygen, relevant microorganism will

not be able to decompose the organic material. Organic material will rot and emit foul gases (odor).

• Sufficient oxygen supply is ensured through aeration / ventilation, either by frequent turning of

compost heaps, by passive aeration (e.g. perforated aeration pipes) or active aeration (e.g. air blower

pushing air into compost heap).

• It is not possible to provide too much oxygen. However, a high aeration rate may leads to the

dehydration of the compost matrix.

1

Moisture content

• The compost matrix should not be too wet or too dry. Ideally, a roof is protecting the compost heap

from direct solar radiation (leading to dehydration) or rain.

• The ideal moisture content can be assessed by squeezing the compost matrix in a palm of a hand:

the compost matrix should be wet but should not drip.

• If compost matrix is too dry, it needs to be watered (use of water or compost leachate).

• If compost matrix is too wet, it needs to be mixed with dry organic material (e.g. sawdust, dry leaves

etc.).

Carbon-to-nitrogen ratio (C/N)

• Compost matrix should always consist of different organic materials: “greens” with high nitrogen

content, and “browns” with high carbon content. For example, leaves (high in carbon, low in nitrogen)

can be blended with food waste (high in nitrogen) to balance the C/N ratio.

• C/N ratio ranging from 20/1 to 25/1 is ideal.

• For a rough estimation, the C/N ratio of a compost matrix can be estimated using literature values:

the percentage of the different organic fractions are multiplied by its specific C/N ratio (for specific

C/N ratios of organic waste see “Composting and Its Applicability in Developing Countries”, 2000.

https://documents1.worldbank.org/curated/en/483421468740129529/pdf/multi0page.pdf).

Temperature measurement

• Temperature measurements can be used to assess the performance of the composting process.

• If moisture content, aeration, and C/N ratio are ideal, the development of heat can be observed in the

inside of compost heap (or if no heat development can be observed, check the degree of aeration,

moisture content and C/N ratio).

• Temperature measuring devices, ideally with long probes, are widespread and inexpensive.

• The temperature increase in compost heaps can kill pathogens and inactivates weed seeds, and

correspondingly leads to an increased compost quality.

Presence of impurities

• Impurities needs to be removed from organic waste before composting, particularly any visible plastic,

metal, glass and/or e-waste (such as batteries). The goal is to reduce the likelihood of contamination

of the final compost by heavy metals or chemical compounds.

• If not removed impurities can contaminate the environment and water bodies, or enter the human

food chain.

• If impurities are removed, domestic organic waste has usually low level of contamination and can be

composted for gardening, reforestation and land restoration purpose. For this reason, it is not

advisable to mix in the same composting process domestic and drain organic waste, as waste in drains

may contain other pathogens and components from different nature and monitoring approach.

For more information on composting, please download the following guidance document: “Decentralised

Composting for Cities of Low-and Middle-Income Countries - A Users’ Manual”, 2006

https://www.eawag.ch/fileadmin/Domain1/Abteilungen/sandec/publikationen/SWM/Decentralized_Compo

sting/Rothenberger_2006_en.pdf

Advantages of composting and the use of compost:

To the soil (use of compost):

• Improves the structure of soil allowing better moisture, infiltration and water retention.

• Improves the level of nutrients and protects against plant disease due to nutrient deficiencies.

• Neutralizes the soil and reduce the use of chemical fertilizers which minimizes environmental impacts.

To the camps (composting activities):

• Reduce significantly the volume of waste to the landfill and cost of transportation.

• Reduces methane emissions from waste and lowers the camp carbon footprint.

• Reduces smell of inorganic waste significantly, and lowers potential of waste as breeding ground for

disease vectors

2

Types of compost methods in camps

Windrow Composting Windrow Composting Windrow Composting

(tray aeration) (pipe aeration) (piling, manual aeration)

Camp 16 – Camp 1E– Camp 17 –

UNICEF, Care Bangladesh UNHCR, BRAC UNICEF, NGOF

Total Area: - Total Area: - Total Area: 600 sqm

No of chamber: 10 No of chamber: 3 (10x5,5m) No of chamber: 3

Cap.per chamber: - Cap.per chamber: - Cap.per chamber: -

Total capacity: - Total capacity: - Total capacity: -

Cycle Duration: 42 days Cycle Duration: 45-60 days Cycle Duration: 30-35 days

Estimated cost: 7,500 USD Estimated cost: - Estimated cost: 16,500 USD

Population: 21,838 ind. Population: - Population: -

Click here for more details Click here for more details Click here for more details

Barrel composting Vermicomposting Pit Composting

Camp 10 - Camp 15 - Camp 15,

IOM, BRAC UNICEF, World Vision UNICEF, World Vision

Total Area: - Total Area: - Total Area: -

No of barrel: 8 No of Rings: 3 No of pits: 3

Cap.per barrel: - Cap.per chamber: 60-80 Kg (waste) Capacity per pit: 60,000Kg

Total capacity: 800 Kg + cow dung (15-20Kg) + sand/soil Total capacity: 180,000Kg

Cycle Duration: 30-35 days (10-15Kg) + 2,000 vermin pcs. Cycle Duration: 170-190 days|

Estimated cost: 2,555 USD Total capacity: 160-180 Kg

Population: 5,000 ind. Cycle Duration: 60-65 days Estimated cost: -

Click here for more details Estimated cost: 111 USD

For other examples in country, click

Product: - here

Click here for more details

Challenges and context

− If organic waste is not segregated at source, it challenges the quality of the compost produced as it

usually contains impurities, such as plastics and other non-organic material or hazardous waste.

− If organic waste is not collected daily, it creates smell and attracts disease vectors.

− Lack of space in the camps for compost facilities, may challenge the capacity to compost all organic

waste generated.

− If insufficiently aerated / ventilated, compost matrixes will emit greenhouse gases (contributing to

climate change) and foul gases (odor nuisance). Furthermore, the organic material starts to rot

(anaerobic decomposition) and becomes less appropriate for plant growth.

− Leachate from composting should be collected. It can be used as liquid fertilizer (need for dilution with

water; water to leachate 1:5 - 1:10) or to rehydrate the compost heap (in case compost is too

dry)Obtaining a license for selling branded compost (marketing) is a time-consuming process.

3

Alternatively, compost can be sold unbranded or supplied to camp activities, such as for plantation or

gardening purpose.

Compost method criteria selection

Land Production

SL Compost method Budget requireme time Remarks

nt

• 8 barrels can cover one block or sub-block.

• Less compost production rate per m2.

1 Barrel composting Low High Moderate • Does not require high technical skills for operation.

• Disadvantage: aeration might be reduced due to

barrel setup.

• Suitable Temperature: 15-25 ˚C (or else can harm the

worms).

2 Vermicomposting Low High Moderate • Less compost production rate.

• Ideal for kitchen waste only (mix of greens and

browns can lead to high temperatures which is

harmful for worms)

• Easy to construct pit within minimum time and less

cost.

3 Pit composting Low Less High • It requires shed to prevent from rain and sunlight

exposure.

• Requires frequent turning to provide sufficient

aeration / ventilation

4 Windrow compost Moderate High Moderate • It requires more technical skill for operation.

(Tray aeration)

Windrow compost • Reduced effort for operation: Less turning required

5 (Pipe aeration) Moderate High Moderate as aeration pipes provide oxygen

• Efficient use of space for composting

Windrow compost • Simple operation: Turning is very easy. However,

8 (Piling, manually Less Less Short manual turning of compost rows is labor-intense

aeration) • Short construction time & low cost.

4

no reviews yet

Please Login to review.