295x Filetype PDF File size 0.10 MB Source: inis.iaea.org

Realtime Aspects of PulsetoPulse Modulation

Riedel, Werner RSsch

Rudolf Steiner, Claus

5100 Darmstadt, Germany

GSI, Postfach 110552, D(

Abstract Graphic workstations are the operators' I/O tools

and software development platforms. The work

The pulsetopulse modulation of the SISESR stations are linked to a communication backbone.

control system is described. Fast response to Ethernet, Token Rings, or fiber optic links are

operator interaction and to changes in process candidates. The choice rather depends on the

conditions is emphasized as well as the essential distances to be mastered than on technical ad

part played by the timing system in pulsetopulse vantages or disadvantages.

modulation. To the same backbone, eventually as sub

networks with bridges in big systems, the equip

I INTRODUCTION ment control computers are connected, which are

mainly VME, Multibus, or CAMACbased.

The benefits of pulsetopulse modulation in accel Extensive use of graphics and CASE tools has

eration operating have been described as early as made an essential improvement in the operator's

'77 [1]. It is an effective way to increase the over and software designers' access to control systems.

all output of valuable beamtime of one or more The overall trend is from very special systems

accelerators. With beamsharing, rarely all users tailored to the very special task of accelerator con

of the beam will be unable to accept the beam at trol towards more uniform, general purpose sys

the same time. If the PPMhandling quickly re tems and the use of standards of the marketplace.

sponds to changing conditions, there will be virtu On the process level, however, the special needs

ally no deadtime in the machine operating due to of accelerator control, mainly realtime and syn

inevitable deadtimes of experiments, e.g. during chronisation, do still exist or are beconung even

new experimental setups. more complex. Therefore the functionality of a

In a multiaccelerator facility, PPM is almost control system must be biased by a timing sys

imperative. Asynchronously running machines, tem. The diversity of control systems of old has

every one of them operating as an injector for the it's evolutionary relic in the diversity of timing

next one, normally have time left between subse systems, which will resist standardisation trends

quent injections that can be used for experiments. for another while. The more the higher levels

in a control system become general purpose (and

II CONTROL AND TIMING SYS less realtime), the more processspecific problems

must be solved on the lower levels. This is the

TEMS domain of the timing system, the equipment con

trollers, and, of course, the equipment hardware.

Much has been said and will be said at this confer In the trend to general purpose systems the design

ence about the major trends in control systems in of the timing system determines the overall per

the last decade. Most systems recently designed formance significantly. The functionality of the

or upgraded are looking more and more similar: timing system may range from simply providing

345

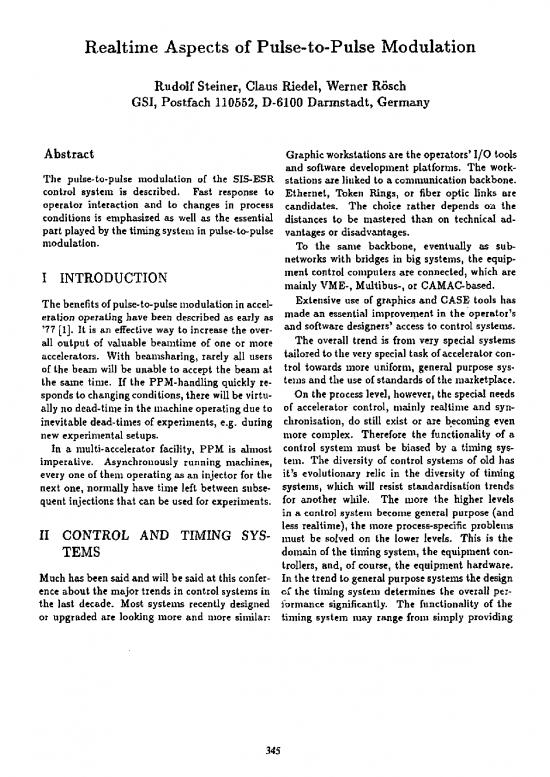

clock signals for subsystem synchronisation to so III.1.2 Online Management

phisticated timing control of the equipment con

trol computers. However: A control system is only The operator may have a need to change either

complete with a timing system (Fig.l). the supercyde or the timing of an individual cycle.

The presently running cycle continues unchanged,

but the next one will have the modifications.

S3 & WORKSTATIONS

III. 1.3 Process Driven Management

COMMUNICATION

1 BACKBONE Process conditions may change and need fast re

EQUIPMENT sponse (suspend immediately one type of cycle of

CONTROL

COMPUTERS the supersycle) or even very fast response (emer

gency, dump the presently running cycle). Evi

dently this is beyond the operators' abilities and

TIMING must be handled on the process level.

SYSTEM For fast response, a request mechanism is very

useful: Cycles are only executed upon request.

Figure 1: A complete control system This is the appropriate level to feed in additional

conditions, as shown in Fig.2. Effective exploita

tion of beamtime is not the only aspect of PPM.

Security, radiation protection etc. are other ones:

A high energy beam must not be generated if it

PPMMANAGEMENT IN REAL cannot reach it's destination point properly.

III

TIME

Exparlaant an vanta baari?

III.l Realtime Demands of PPM ' SacuMty In «*r« *n7

' Hagnala in aara an ok?

vacuum in aara *n ok

vnat alaa nava you in *n..

The control system of Fig.l already contains all

realtime and synchronisation mechanisms to man Figure 2: Request Level

age the process, e.g. to execute a synchrotron

cycle. A system that can execute one cycle can Emergency handling is too special in every accel

as well execute another one. Nothing principially erator environment to be discussed here.

new needs to be introduced to perform PPM.

What then could be the realtime aspect of

PPM? Let me call it the 'online supeicycle man III.2 An Example: PPM Management

agement'. at SISESR

There are three levels of access to supercycle

management, with increasing realtime demands: Fig.3 shows the control and timing system of SIS

ESR. The timing system drives a timing network

in parallel to the communication network. Tim

III.1.1 Offline Management ing interfaces receive the serial timing information

and pass it as a 16bit parallel code, the event

The supercycle is built up offline to fit the exper code, to the equipment control computers.

imental program. The internal timing of the in A selectable set of events is transformed to

dividual cycles is programmed at the same time. hardware triggers for equipment by the timing in

There is no realtime demand. terfaces. The time jitter for triggers is smaller

346

than ±.5 microseconds in the system. Nanosec In comparison to other PPMsolulions, e.g. [3], no

ond timing has been left to special solutions to special PPMmanagement components like PPM

keep the timing system hardware simple. message decoders are needed at the process conrol

In contrast to Fig.l the timing system in Fig.3 level.

is not a special part in the control system. To the Fig.5 gives the operator's view of a simple super

operator it looks as, and in fact is, just another cycle.

equipment control computer.

D C D NC

? .5

WORKSTATIONS Count2 Count1 CountS

Active Active Inactive

R R NR

BACKBONE Figure 5: A SIS Supercycle

TIMING NETUORK

The properties assigned to each cycle are

EOUIPMENT I/O active/inactive

AND TRIGGERS execution count

decement/nondeciement

TIF: TIMING contiguous/noncontiguous

INTERFACES

all of which can be changed online by the opera

Figure 3: The SISESR Control Architecture tor. Active/inactive provides a simple means to

suspend a cycle. An inactive cycle does not leave

The SISESR timing system has direct timing a gap in the supercycle. It continues with the next

control over all equipment control computers [2]. active cycle.

Each equipment control computer has available The execution count works together with

complete settings to execute sixteen different cy (non)decrement and (non)contiguous.

cles, the 'virtual machines'. In nondecrement condition, (non)contiguous

The timing system activates machines by pro is meaningless. The subsequent supercycles are

viding the eventcode (Fig.4). The equipment identical containing as many individual cycles in

controllers do nothing unless they receive events, sequence as set by the count number.

command events, if nothing else, when no cycle With decrement and noncontiguous, the cycle

is active and the timing system is idle. In fact, will show up once in as many supercycles as set

the timing system of the SISESR is a hardware by the count, and suspended in the following su

dispatcher to compensate for the loss of realtime percycles.

abilities on higher control levels: It is the tim With decrement and contiguous, the cycle is ex

ing system that makes a 'real machine' out of a ecuted as many times as set by the count in only

'virtual machine'. This given, it is the natural one supercycle.

candidate to be the 'supercycle manager'. One type of cycle may show up at different

places in the supercycle, giving a high flexibility

for supercycle programming.

EVENT BUS Fig.6 gives an overview of the supercycles re

EOUIWCNT

is pit * my sulting from different settings provided the status

CONTROL

CO*»UTER from the request level is 'true'. If 'false', the cycle

CW»

no reviews yet

Please Login to review.