267x Filetype XLSX File size 0.05 MB Source: open.alberta.ca

Sheet 1: Prefabrication Checklist

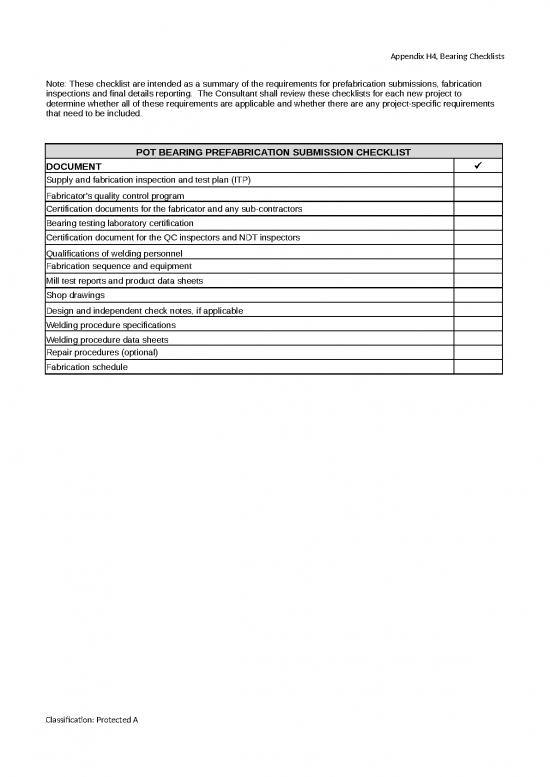

| Note: These checklist are intended as a summary of the requirements for prefabrication submissions, fabrication inspections and final details reporting. The Consultant shall review these checklists for each new project to determine whether all of these requirements are applicable and whether there are any project-specific requirements that need to be included. | |

| POT BEARING PREFABRICATION SUBMISSION CHECKLIST | |

| DOCUMENT | ü |

| Supply and fabrication inspection and test plan (ITP) | |

| Fabricator's quality control program | |

| Certification documents for the fabricator and any sub-contractors | |

| Bearing testing laboratory certification | |

| Certification document for the QC inspectors and NDT inspectors | |

| Qualifications of welding personnel | |

| Fabrication sequence and equipment | |

| Mill test reports and product data sheets | |

| Shop drawings | |

| Design and independent check notes, if applicable | |

| Welding procedure specifications | |

| Welding procedure data sheets | |

| Repair procedures (optional) | |

| Fabrication schedule | |

| POT BEARING QUALITY ASSURANCE INSPECTION CHECKLIST | ||

| Bearing Location and Identification Number: | ||

| Phase of Fabrication | Quality Assurance Inspection Requirement | ü |

| Supply of Material | Verify all the steel plates received match the heat numbers listed on the MTRs submitted to the Consultant for review and acceptance as part of the prefabrication submittals | |

| Verify all material requiring verification testing is properly sampled | ||

| Review QC inspection and testing records and/or reports of other procured materials such as PTFE, stainless steel and fasteners for conformance with the contract | ||

| Plate Cleaning and Inspection | Verify each steel plate is marked with a heat number corresponding to an accepted MTR | |

| Visually inspect steel plates to assess their cleanliness or presence of damage | ||

| Verify repairs, if required, have been completed in accordance with the repair procedure that has been reviewed and accepted by the Consultant | ||

| Verify steel is stored in a dry place to minimize corrosion damage prior to fabrication | ||

| Review QC inspection and testing records and/or reports for conformance with the contract | ||

| Cutting of Plate | Verify cutting of plate is completed using an acceptable procedure | |

| Verify roughness of cut plate edges meets the contract requirements | ||

| Review QC inspection and testing records and/or reports for conformance with the contract | ||

| Welding | Verify welders, welding operators and tack welders working on the project are qualified to perform the task assigned and that their certification is current | |

| Verify that the welding consumables are stored in accordance with AASHTO/AWS D1.5M/D1.5 | ||

| Verify the steel surfaces have been acceptably prepared and cleaned prior to welding | ||

| Verify welders are correctly using the reviewed and accepted WPDS’s for the applicable joint and weld type | ||

| Verify that preheat and interpass temperature requirements are in accordance with the reviewed and accepted WPDS and SSBC | ||

| Verify cleaning is taking place between weld passes in multi pass welds | ||

| Visually inspect all completed welds | ||

| Complete QA NDT if QC reports are not consistent with visual inspection results | ||

| Review QC inspection and testing records and/or reports for conformance with the contract | ||

| Provide the fabricator with QA inspection and testing records and/or reports | ||

| Provide written acceptance of the hold point in the supply and fabrication ITP | ||

| Machining | Verify dimensions and tolerances of individual bearing components by performing spot checks | |

| Review QC inspection and testing records and/or reports for conformance with the contract | ||

| Provide written acceptance of the witness hold points in the supply and fabrication ITP | ||

| Galvanizing, Metallizing and Coating | Verify surfaces are acceptably prepared and cleaned prior to coating | |

| Visually inspect coating after application | ||

| Review QC inspection and testing records and/or reports for conformance with the contract | ||

| Inspection and Testing of Completed Bearings | Verify bearing plate roughness and flatness by spot checking | |

| Verify dimensions of bearings by performing spot checks | ||

| Verify all bearing testing has been completed in accordance with Subsection 8.3.7.3 of the SSBC | ||

| Review QC material and load inspection and testing records and/or reports for conformance with the contract | ||

| Provide written acceptance of the witness and hold points in the supply and fabrication ITP | ||

| Embrittlement Inspection and Testing of High Strength Anchor Rods | Review QC material verification inspection and testing records and/or reports for conformance with the contract | |

| Provide written acceptance of the hold point in the supply and fabrication ITP | ||

| Final Inspection | Review of the QC and QA inspection and testing records and/or reports to verify compliance with the contract documents | |

| Ensure all repairs have been completed, and all non-conformance reports have been reviewed and accepted | ||

| Written acceptance of the hold point in the supply and fabrication ITP is provided | ||

| Clearance to Ship | Verify bearings are acceptably loaded, supported, restrained and protected for transportation | |

| Bridge File #: | ||||||

| POT BEARING | Date: | |||||

| FABRICATION INSPECTION FORM | By: | |||||

| Page: of | ||||||

| Bearing Identification Number: | ||||||

| Fab. Mark Number: | ||||||

| Inspection Items | Yes | No | ||||

| Dimensions per shop drawings | ||||||

| SS sheets in contact with PTFE continuously welded to backing plate | ||||||

| Weld is clean, uniform, without overlaps, outside of PTFE contact area | ||||||

| PTFE bonded and recessed in a rigid backing materal | ||||||

| Rigid backing material shall be grit blasted and cleaned | ||||||

| PTFE guides and restraints extends to 10 within ends of backing plate | ||||||

| Metal to metal contact surfaces machined | ||||||

| Smooth finish on all edges and surfaces | ||||||

| All weld spatter and flux residue removed prior to galvanizing | ||||||

| Hot dip galvanizing | ||||||

| Cleaning and pickling of anchor rods | ||||||

| Pot and piston plate surfaces not in contact with elastomer metallized | ||||||

| Barrier coating on bottom of each base plate | ||||||

| Verification of QC Testing | Yes | No | ||||

| Elastomers tested to Section 8 of AASHTO M251-06 | ||||||

| Magnetic particle testing on 25% of fillet and partial penetration welds | ||||||

| Hardness test of elastomers | ||||||

| Adhesion test of fully cured coating per ASTM D3359 | ||||||

| Inspection Notes | ||||||

no reviews yet

Please Login to review.