444x Filetype XLS File size 0.16 MB Source: www.volvogroup.com

Sheet 1: Prepare FMEA

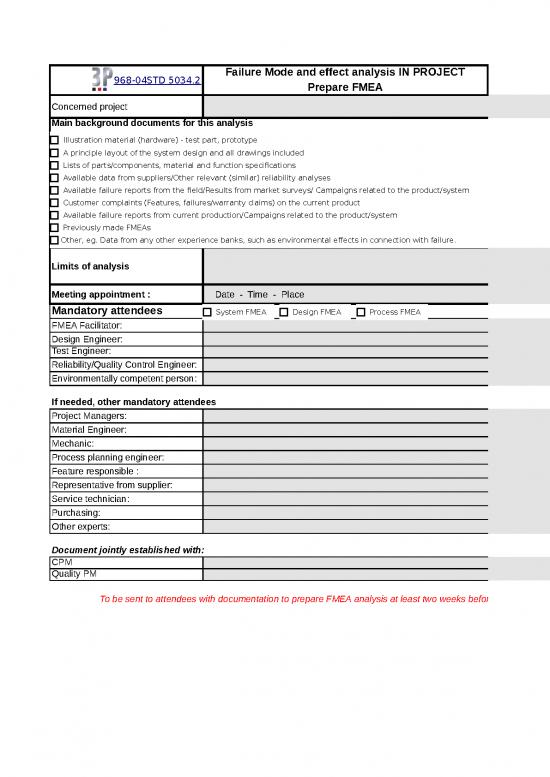

| GDI 968-04 STD 5034.2 | Failure Mode and effect analysis IN PROJECT | Date : |

| Prepare FMEA |

|

|

| Concerned project |

|

|

| Main background documents for this analysis | ||

| Limits of analysis |

|

|

| Meeting appointment : | Date - Time - Place | |

| Mandatory attendees | ||

| FMEA Facilitator: | ||

| Design Engineer: |

|

|

| Test Engineer: |

|

|

| Reliability/Quality Control Engineer: |

|

|

| Environmentally competent person: |

|

|

| If needed, other mandatory attendees | ||

| Project Managers: |

|

|

| Material Engineer: |

|

|

| Mechanic: |

|

|

| Process planning engineer: |

|

|

| Feature responsible : |

|

|

| Representative from supplier: |

|

|

| Service technician: |

|

|

| Purchasing: |

|

|

| Other experts: |

|

|

| Document jointly established with: | ||

| CPM |

|

|

| Quality PM |

|

|

| To be sent to attendees with documentation to prepare FMEA analysis at least two weeks before meeting | ||

| FMEA - FAILURE MODE AND EFFECT ANALYSIS SYSTEM/DESIGN/PROCESS | |||||||||||||||||||||||

| Main system / Sub-system | Part/Operation name. | Drawing-Part No. | Machine No. | Functional Specification-Technical Regulation (link if possible) | Supplier | ||||||||||||||||||

| 0 | 0 | ||||||||||||||||||||||

| Main Function / Operation | Date Performed | Date Time Updated | Status - Hardware/Digital modell | Issued by | Project | Issue | |||||||||||||||||

| 8/3/2022 17:29 | 0 | ||||||||||||||||||||||

| PART | CHARACTERISTICS OF FAILURE | 1st RATING | ACTION-STATUS | 2nd RATING | 0 | RPN High | RPN Medium | RPN Low | |||||||||||||||

| No | Function / Part / Operation | Failure mode | Causes of failure | Undesirable customer effects Effects of failure on syst. / part / operation |

Testing - Simulation | Po | S | Pd | RPN | Recommended action | Planned action | Responsible | Follow up date | Po | S | Pd | RPN | Verifications-Sign | 0 | 0 | 0 | ||

| 1 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 2 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 3 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 4 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 5 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 6 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 7 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 8 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 9 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 10 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 11 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 12 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 13 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 14 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 15 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 16 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 17 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 18 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 19 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 20 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 21 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 22 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 23 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 24 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 25 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 26 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 27 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 28 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 29 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 30 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 31 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 32 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 33 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 34 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 35 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 36 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 37 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 38 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 39 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 40 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| 41 | 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||

| Please enter drawings, technical descriptions and other documentation that can increase understanding of area which is analysed |

||||||||||||||

| Details as input for the analysis (data,hardware, picture etc.) | ||||||||||||||

| Details for evaluation (experience, significant failure mode or problem) | ||||||||||||||

no reviews yet

Please Login to review.