293x Filetype PDF File size 2.38 MB Source: ftp.idu.ac.id

DBA 1651 PRODUCTION MANAGEMENT

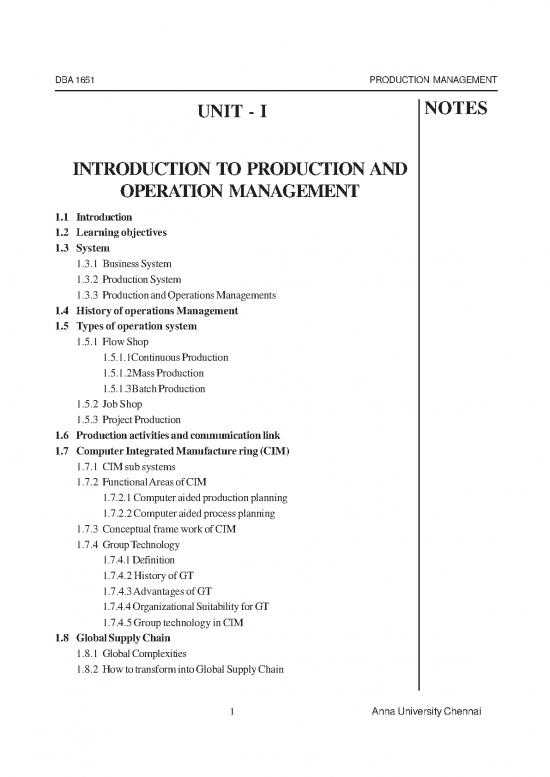

UNIT - I NOTES

INTRODUCTION TO PRODUCTION AND

OPERATION MANAGEMENT

1.1 Introduction

1.2 Learning objectives

1.3 System

1.3.1 Business System

1.3.2 Production System

1.3.3 Production and Operations Managements

1.4 History of operations Management

1.5 Types of operation system

1.5.1 Flow Shop

1.5.1.1Continuous Production

1.5.1.2Mass Production

1.5.1.3Batch Production

1.5.2 Job Shop

1.5.3 Project Production

1.6 Production activities and communication link

1.7 Computer Integrated Manufacture ring (CIM)

1.7.1 CIM sub systems

1.7.2 Functional Areas of CIM

1.7.2.1 Computer aided production planning

1.7.2.2 Computer aided process planning

1.7.3 Conceptual frame work of CIM

1.7.4 Group Technology

1.7.4.1 Definition

1.7.4.2 History of GT

1.7.4.3 Advantages of GT

1.7.4.4 Organizational Suitability for GT

1.7.4.5 Group technology in CIM

1.8 Global Supply Chain

1.8.1 Global Complexities

1.8.2 How to transform into Global Supply Chain

1 Anna University Chennai

DBA 1651 PRODUCTION MANAGEMENT

NOTES UNIT - I

INTRODUCTION TO PRODUCTION AND

OPERATION MANAGEMENT

1.1 INTRODUCTION

This unit starts with a definition of a system. In this unit production system and

its objectives are explained along with the components of a system. The history of

operations management is portrayed. The various functions of production system and

their interlinking are explained through a flow chart. The components of computer,

integrated manufacturing and their purpose are dealt. Finally, the recent trend in the

operations, namely, Global Supply Chain is introduced in this unit.

1.2 LEARNING OBJECTIVES

· To know the importance of the production system in an organization.

· To understand the link between various activities of the production system.

· To comprehend the history of operations management.

· To understand the components of computer integrated manufacturing

1.3 SYSTEM

It consists of elements or components. The elements or components are

interlinked together to achieve the objective for which it exists. Eg: human body,

educational institutions, business organizations.

Components of a system:

The input, processing, output and control of a system are called the components

of a system.

Anna University Chennai 2

DBA 1651 PRODUCTION MANAGEMENT

Figure 1.1 - Components of a system NOTES

Input Output

Processing

Feedback

Control

Control:

There are two types of control, namely Proactive Control and Reactive

Control.

Proactive Control:

When an operation is carried out on a product in a workstation, the quality

inspector goes to the workstation and inspects the product. When the samples that he

has taken for the inspection are not confirming to the quality, he stops the machine and

identifies the reason for the deviation and corrects the problem, so that the produced

product thereafter conform to the specifications. This type of control prevents any

major quality setback after the production. This is an example for proactive control.

Reactive Control:

In a planning period, usually the quality target is fixed. Suppose, an organization

feels to fix 5% defective is safe in the targeted production quantity and assumes that at

the end of the planning period it finds that the defective output exceeds the targeted

defective products. Then, it has to find out the reason for the deviations, namely, whether

the problem is due to the method of doing the work or the resources used in the process.

Then the planner uses this knowledge to prevent any problem in the future. Thus a

Reactive Control is a post morterm case.

1.3.1 Business System:

The business organization is classified into different subsystems based on the

functions like marketing, production/operation, finance and human resource etc.

3 Anna University Chennai

DBA 1651 PRODUCTION MANAGEMENT

NOTES Figure 1.2 – Business System

Marketing Finance

Human Resource Production/Operation

Each subsystem will have more sub subsystems.

1.3.2 Production / Operation System

Figure 1.3 – Production / Operation System

Input Transformation Output Objectives

Process

1. To produce the required quantity.

Capital

Man Power Goods 2. To achieve the required quantity.

Material

Information Services 3. To meet the delivery time.

4. Economical way of doing

Operations Management

Operation system is either manufacturing sector or service sector. The input

requirements are shown in figure1.3 The transformation process, in which part of the

value addition takes place to get the required quantity of the product or services with

the targeted quality within the specified time period, is carried out in a most economical

way. Operation Management Plan coordinates and controls all the activities in the

operation system to achieve the stated objectives.

Thus (the activities listed in the diagram) the Operations Management activities,

ensure the objective of quantity, quality, delivery time and economical way of doing

work. The communication link between the various activities are shown in the figure1.3.

Each activity is dealt in detail in different sections of this material. This figure

(figure1.3) will be very much appreciated after getting a clear understanding of all the

activities.

Anna University Chennai 4

no reviews yet

Please Login to review.